Flexibility and reliability

at every stage of the process

Plan has always been committed to machining tubes of varied materials and sizes, while not forgetting to guarantee a range of extremely efficient additional services.

Thanks to a well-organised corporate team with defined roles and continuous training, Plan provides constant advice for the design of specific products, assembly and shipping as well as an attentive and prompt after-sales service.

Design and technical advice

The technical department has highly skilled staff capable of creating and managing projects from start to finish while always paying attention to the diverse customer requirements.

Our technical support guarantees that the requested machining operations can be carried out with the help of state-of-the-art software that can manage the work and simplify the entire production process.

Renderings of the parts are delivered so they can be best adapted to the finished product and have the assurance of precision during production.

All prototypes and equipment for subsequent serial production are developed in-house on the basis of 3Ds provided by the customer.

Research and Development

Thanks to continuous investment in purchasing new machinery, Plan has always aimed at complying with the new Industry 4.0 standards, thus enabling production to be connected to the internet and being able to monitor the entire production process in detail, as well as optimising time and resources.

Quality control

The manufacturing process at Plan does not end with production and surface treatments but continues with thorough quality control and careful management of the assembly, packaging and logistics stages. Every product, whether processed in-house or by external suppliers, undergoes overall quality control before proceeding to the next processing stages.

Quality control is an essential step to ensure that products fully meet the required standards and customer specifications. Only after thorough inspection are the components assembled and prepared for delivery.

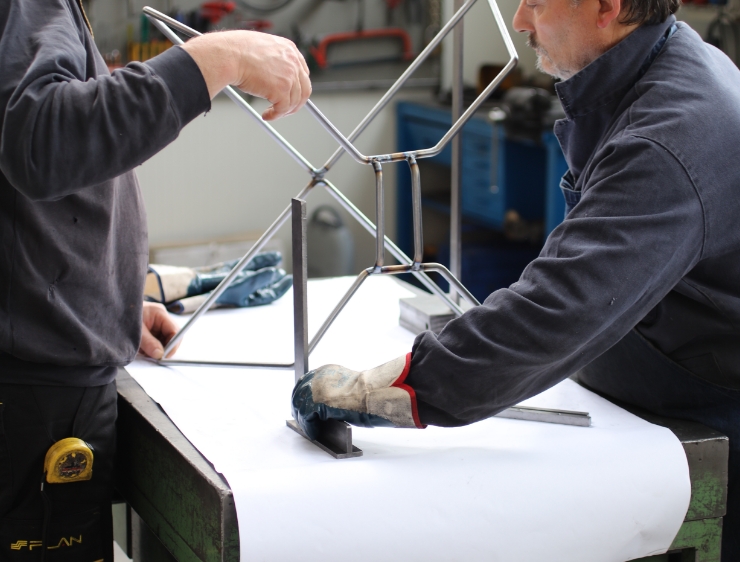

Serial and contract production

Plan professionally manages any type of production. In fact, the serial production of machined metal tubes, as well as contract production, is a corporate distinction.

We work on orders, starting from well-studied projects in cooperation with the technical department, so that we are able to produce a specific, well-defined product with the technical details pre-established together with the customer.

Assembly

Plan offers extensive flexibility in the assembly and packaging process, adapting to the specific needs of each customer. We work with qualified suppliers to offer a variety of packaging solutions, including plastic, wood and cardboard materials, to ensure that products are perfectly protected during transport.

Plastic packaging: for items that require light but strong protection.

Wood packaging: ideal for heavy or fragile parts that need extra strength.

Cardboard packaging: ecological and versatile solutions, perfect for lighter or less fragile products.

Plan ensures each package is designed and made to fit the product's specifications and safety requirements during transport.

Logistics

In addition to quality control and packaging, Plan offers an integrated logistics service, with the possibility of managing transport to the customer's final destination. By working with logistics partners and using our own or contracted vehicles, we are able to offer fast and reliable delivery solutions, responding promptly to the needs of specific timescales and destinations.

Integrated solutions for your company’s success. Contact us now

for customised solutions that guarantee quality and timeliness.

contact us