Tube cutting, bending,

welding and treatments

Plan machines any type of tube thanks to state-of-the-art technology capable of performing specific machining required for certain finished products intended for sectors such as industry, interior and exterior furniture, agriculture and much more.

Attention and excellent work management are extremely important to Plan, as they are essential for complete, quality work that is in line with customer requirements and their designers.

The company has skilled staff and a research and development department that works on projects that are also fully customised, as well as providing detailed advice and customer assistance.

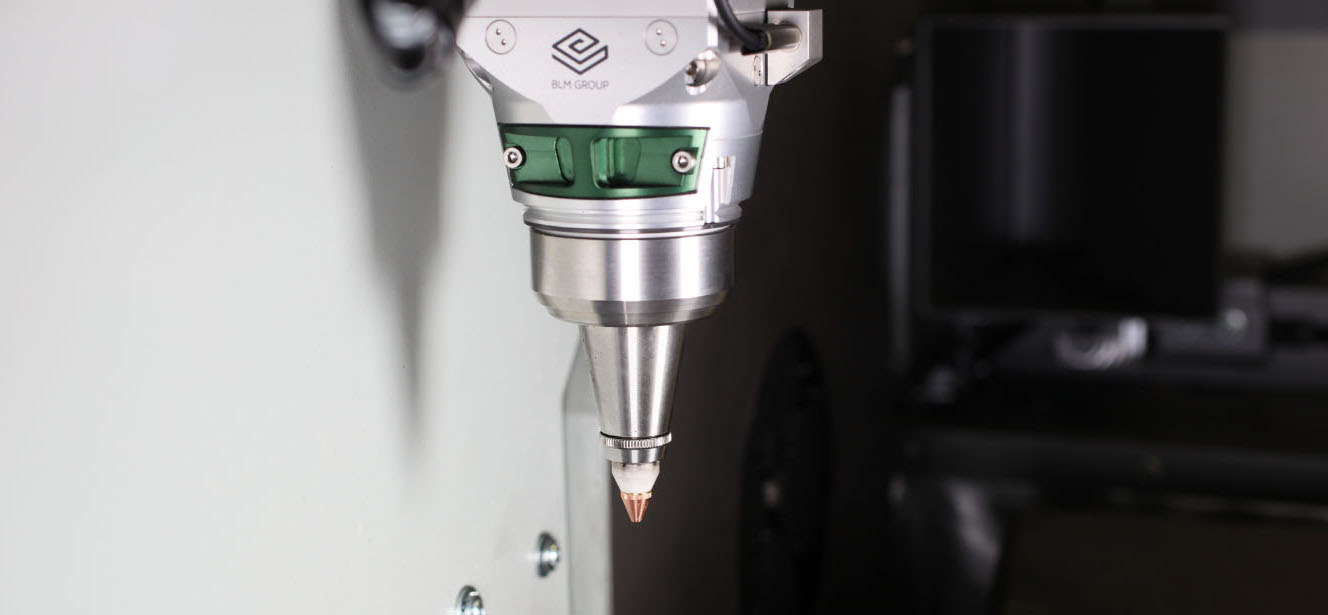

Laser cutting

For laser cutting iron, stainless steel, aluminium, brass and copper tubes of different shapes, sizes and special profiles, tube laser cutting: technology is used: a technique that facilitates material machining and optimisation of the production chain, to minimise production time and waste.

Laser cutting is ideal for grooves, holes, slots, staggered joints, interlocking connections, connect couplings and even complex contours.

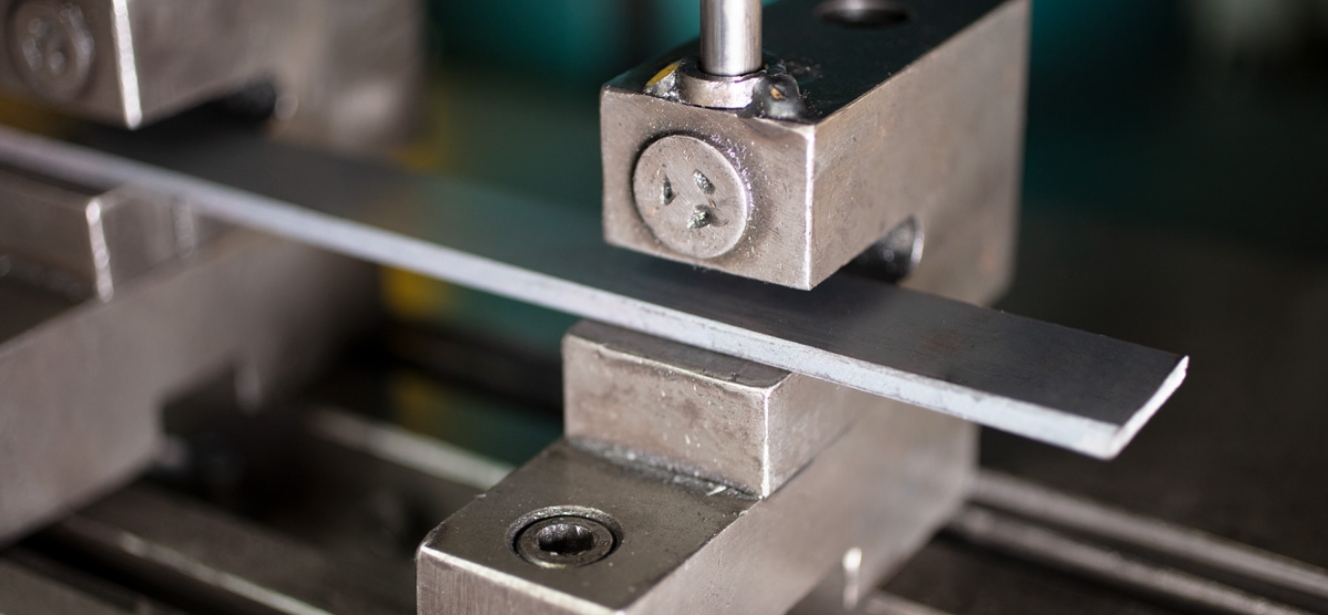

Bending and Turning

Tube bending is an essential process that enables more efficient subsequent machining in the various production processes.

The machines that Plan has at its disposal are tube and wire bending machines and control calendering machines.

The tube bending machines are CNC controlled with an electric variable radius: a choice intended to considerably reduce energy consumption with a view to increasingly safeguarding the environment.

Workshop and tube end machining

With the help of the hydraulic presses in Plan's machine park, tube blanking and stamping can be carried out. The company also deals with drilling to create holes of varied sizes on all types of machinable material by means of chip removal. Threading and shaping are further processes performed in-house.

Tube end machining such as threading, deburring, flattening and toothing is carried out using special dies and specific equipment.

Welding

One of Plan's strengths is MIG, TIG and oxyacetylene tube welding performed with extreme precision. For welding metals such as iron, stainless steel, aluminium, brass or copper, welding robots and manual welding stations are used.

Cleaning operations from degreasing to polishing of steel, stainless steel, aluminium and brass workpieces are carried out when required by the customer.

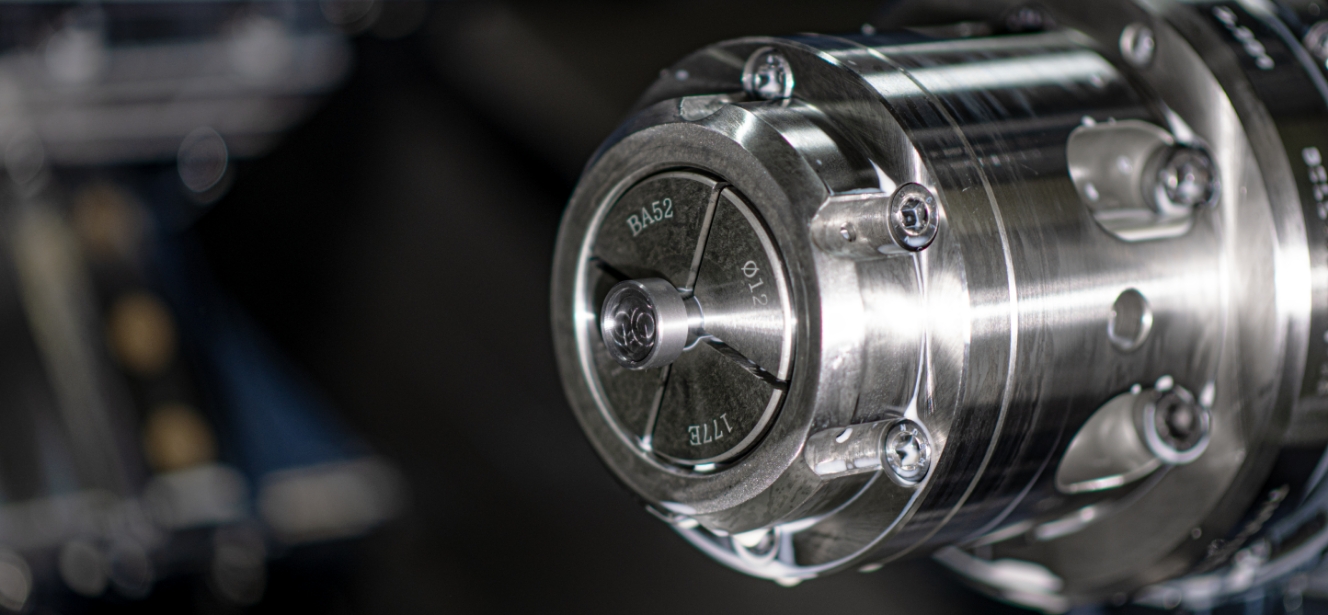

Turning and Milling

Turning is a mechanical machining process that produces parts with precise and detailed shapes, due to using numerically controlled machinery such as CNC lathes, CNC milling machines and manual recovery lathes.

Cleaning and grinding

Through these processes, the products are prepared for chrome-plating and painting surface treatments. The department is equipped with a machine used for cleaning bars and round tubes, as well as special tools and cleaning machines.

surface treatments

Based on specific requests, Plan carries out surface treatments on machined tubes of various formats and materials, including painting, chrome-plating, galvanising, pickling, electro-polishing and nickel-plating.

Powder coating

At its new production facility, Plan performs powder coating in-house, ensuring maximum quality and control at every stage of the process. This treatment provides the tubes with a smooth finish while offering excellent resistance to weathering, wear, and corrosion. The solvent-free process is an eco-friendly choice that combines high technical performance with greater sustainability. With a wide range of available colours and customisation options, this solution is particularly suited to the furniture, design, and broader industrial sectors.